DERBY, England—Rolls-Royce is moving ahead with durability enhancements for the Trent 1000 following the opening of a specialist facility at its headquarters in Derby, England, where it plans to undertake the modifications for the program through to 2027.

The British engine manufacturer opened the aftermarket support facility (ASF) at the start of 2025 to specialize in quick-turn engine services and to undertake the first durability enhancement package for the Trent 1000 program, one of two powerplant options for the Boeing 787 aircraft, alongside the GE Aerospace GEnx.

“The building was identified as footprint that we could quickly adapt to quick turn capacity to complement the certification of the durability enhancement package on the Trent 1000,” says Paul Keenan, Director of Global Aftermarket Operations Civil Aerospace at Rolls-Royce, who says staff additions were also made to ramp up the facility. “We’ve recruited more than 100 people in twelve months, so that we can run at this modification at pace,” he says.

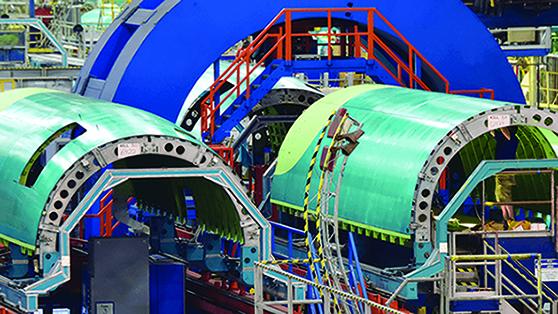

The facility formerly operated as a general tooling storage facility for the Derby campus in a building more than 100 years old. Upgrades to transform the building included investments in new high-load capacity cranes, equipment and offices.

The Trent 1000 has endured durability issues related to its high-pressure turbine (HPT) blades. The manufacturer inducted its first engine at the quick-turn facility in November last year but, following the announcement of the first of two durability enhancement packages for the Trent 1000 in June 2025, the workscopes at the Derby quick-turn facility changed to incorporate the newly certified blade for the Trent 1000 program.

The first durability enhancement package is targeting a 40% increase in cooling air flow to a new HPT blade making it 45C cooler. It updates the combustion system and fuel spray nozzles and also includes enhancements to the engine electronic controller software.

“These upgrades are proven—they’re already delivering exceptional results and, in some cases, tripling time on wing on the Trent 7000 since introduction in 2022,” Keenan says. “As a minimum, based on our testing and as already demonstrated on the Trent 7000, we are expecting more than double the time on wing compared to the current entry into service standard of blade.”

To prepare and mitigate against any potential supply chain constraints, Keenan says Rolls-Royce readied its inventory levels in advance of the HPT blade certification. “We were fully expecting certification and therefore we’ve been building up a stockpile and we are now ready to go,” he says.

Next year, Rolls-Royce will unveil phase two of the durability enhancement package, which will aim for a 30% improvement for Trent 1000 time on wing beyond the first phase’s gains. Included in the package are further enhancements to the HPT blades, advanced coatings for combustor tiles, and cooling and coating changes to the HP nozzle guide vanes. Also included is a redesigned combustor-to-turbine interface, adapted from the latest Trent XWB-84 EP engine. Keenan adds that the phase two upgrades do not require flight testing.

Close to the ASF is Rolls-Royce’s Engine Overhaul Services (EOS) facility, which undertakes heavier engine work scopes and is staffed by around 700 people. Keenan says having the two facilities operating separately from one another—albeit under the same support functions and leadership—enables the ASF to create a targeted facility which “optimizes its methods, equipment and workforce around a standard work scope to drive significant benefits to turnaround time to deliver the durability enhancement package to customer fleets.”

Keenan adds that it will continue to recruit people in line with its growth plans for Derby along with its facility in Dahlewitz, near Berlin in Germany, which has also seen a recruitment drive following the resuming of commercial engine services at the site late last year. Across both shops, the British engine-maker invested £55 million ($70 million), with about half of the investment and two thirds of the jobs created in Derby. “This facility, like Dahlewitz, has taken approximately one year from being approved to being operational. This includes, labor, methods, new tooling and regulatory approval,” Keenan says.

The investment led to a recruitment drive, with the creation of more than 300 front-line operations roles. To prepare for this, the company trained technicians and engineers within its aftermarket network. To Train staff, Rolls-Royce utilized the EOS and ASF sites in Derby, along with the Arnstadt, Germany-based N3 Engine Overhaul business, a Trent-focused MRO joint venture between Rolls-Royce and Lufthansa Technik.